We, Management Progress Association, are a group of Japanese senior leaders, who have been working in the "field or GENBA in Japanese" for many years. We are dedicated to passing on the "practical techniques, skills, wisdom, and expertise" that each of our members has experienced and developed through their work. This handing-down is not only for the companies in Japan but also for the companies in the world's fast-growing countries. We are in the mission to support these people to become leaders in their companies and industries and contribute autonomously based on the practical know-how that they learn from us. Our goal is to help these people to become leaders in their companies and industries, and to contribute to their success.

Our main theme is "productivity improvement (delivery, cost, and quality)" in the manufacturing and service industries.

Our mission: the techniques to ensure the transfer of practical know-how are

(1) Starting from the analysis of specific problems (causes) that occur in the field

(2) Then, “theoretically organize and learn” how to solve the problems which is occurring

(3) Break down the solution method into " specific procedures" to be applied in the field

(4) At last, visualize the KAIZEN contents and to make the KAIZEN contents take root in the organization, "support the implementation of software system" = IT investment =support the advancement of it.

The coaching process described above is called "KAIZEN Coaching".

We also offer training programs to acquire the knowledge system of each specialized field.

Our first-priority is to help our clients solve their problems with sincerity, and we hope to contribute to the true development and prosperity of more companies, societies, and countries.

Takeshi Negishi, President, Management Progress Association

Since late 2022 when the calming-down of the Covit-19’s pandemic, we are preparing to re-start our activities in Vietnam

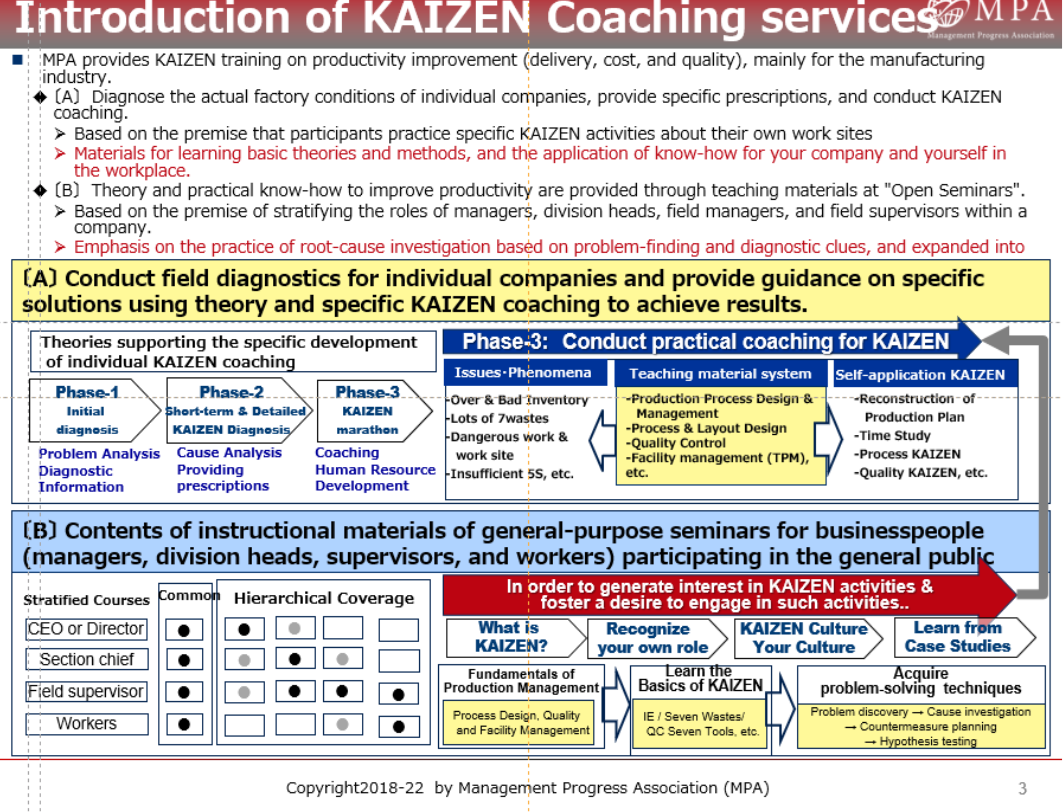

Management Progress Institute 〔MPA〕provides KAIZEN Coaching Services to improve productivity for Manufacturing Industries.

The MPA’s team of active senior members have added to their experiences in various kinds of practical management constantly to improve productivity through long years of collaborating with your subordinates on PDCA basis and related divisions, and continuously conducted KAIZEN activities in the fields of production management, process control and quality control in GEMBA of the manufacturing industries.

We visit factories to perform coaching support by grasping the point of KAIZEN based on practical experiences as follows:

〔1〕diagnose to see if any problems for 2 or 3 hours to identify “what the issues are?”

〔2〕study them to provide the prescript to solve the problem, then in case being understood;

〔3〕conduct cause-analysis in detail to plan & propose what the countermeasures are

〔4〕provide how to solve the issues by showing theories & know-how to customer’s main staffs in charge

〔5〕set up a series of time-period session and take systematized steps to guide & supervise for them to carry out and implement how to conduct KAIZEN activities on hands-on basis

We are going to perform the hands-on based KAIZEN Coaching, mentioned above. to let the customer achieve “Shortening Production-Time, Cost Down, Reducing Failure to establish Quality Assurance”.

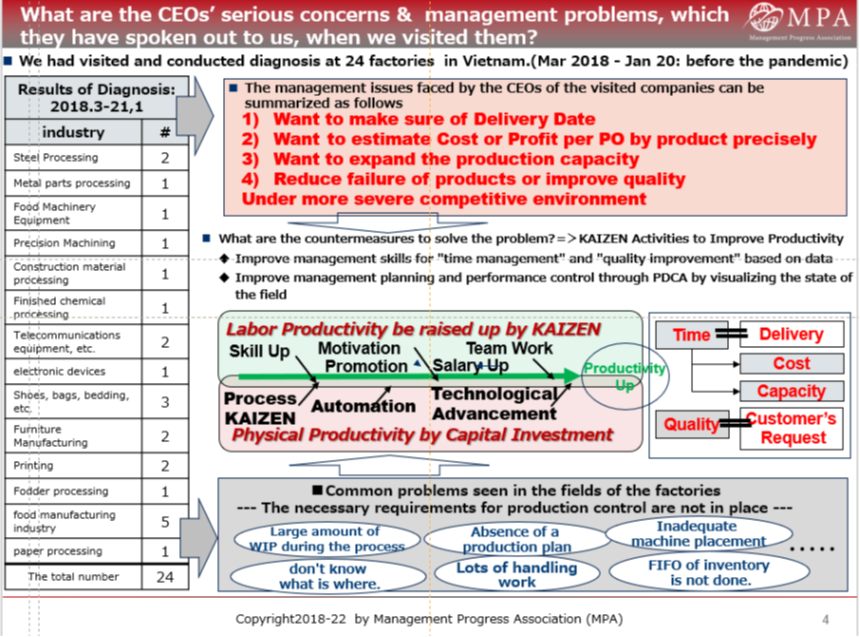

MPA has been conducting KAIZEN Coaching since 2018 for mainly manufacturing industries in Vietnam.

We had visited 24 companies in Ho Chi Minh, Hanoi and Hai Phong for 2 years before the outbreak of Covit-19 pandemic early in 2020, to start with Walking-Through inside the factories in the morning to conduct diagnosis of problematic issues by short looking-In to see in and present, and present our analysis & review on the causes and countermeasures for them to take.

Every time we make it a rule to ask CEOs one question “What are you suffered and concerned with?”, and we have perceived the common issues of problems almost CEOs have wanted to solve.

① Difficult to calculate exactly the delivery data to ship to the customer when receiving PO

② Difficult to estimate the cost incurred and the profit precisely on the respective PO received

③ Want to expand production capacity

④ Reduce the number of failures and improve quality

To improve productivity, two (2) things are critical performing KAIZEN in〔1〕Labor Productivity &〔2〕Capital Productivity: 〔1〕every one’s effort in manufacturing work for KAIZEN and 〔2〕Equipment Investment Automation & Technological Development’s in production technology. These two (2) KAIZEN activities enable to prospect “Delivery Date” & “Production Cost” by “measuring & shortening Production Time, and then lead to ensure to achieve Quality required by customers.

How to proceed with Kaizen Coaching →

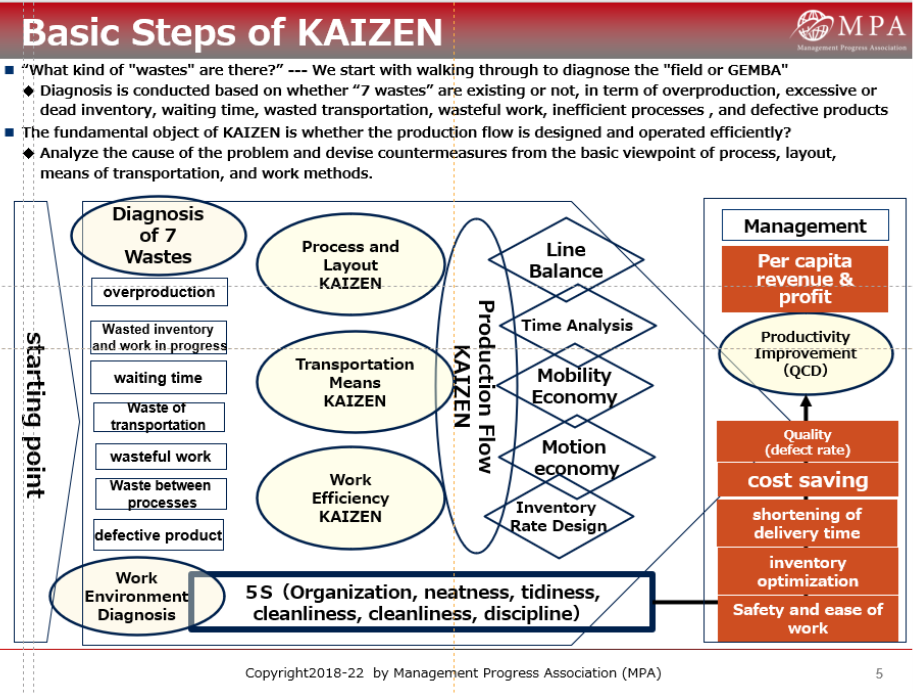

In taking walking-through inside a factory, we notice typical types of ”7 Wastes”: “Excessive Stocks”, “Waiting Time”. “Wasteful Transportation”, “Wasteful Workings”, “Over Production”, “Waste between processes”, “Defective Product”.

After having recognized these wastes, we need to find out “true reasons” which are underlying and eventually causing these problems such as followings, which are needed to be solved:

a. Any problems in designing “Layout in the whole factory”, determining the efficiency of the processes?

b. Any problems in selecting “Transportation Methods”, determining the efficiency of moving the produced or goods on the production line as straightly flowing as possible?

c. Any problems in setting “Workers’ Motion Economy”, determining the efficiency of working of operating machines, processing or/and manufacturing products?

Solving these “Wastes” in the field enables to realize “Productivity Improvement”, and practicing basic “3 S”---“SEIRI〔Organization〕”, “SEITON〔Neatness〕”, “SEISO〔Cleaning〕”--- out of “5 S” by and among teamwork of all workers enables to establish safely, efficiently and safely working environment in the field.

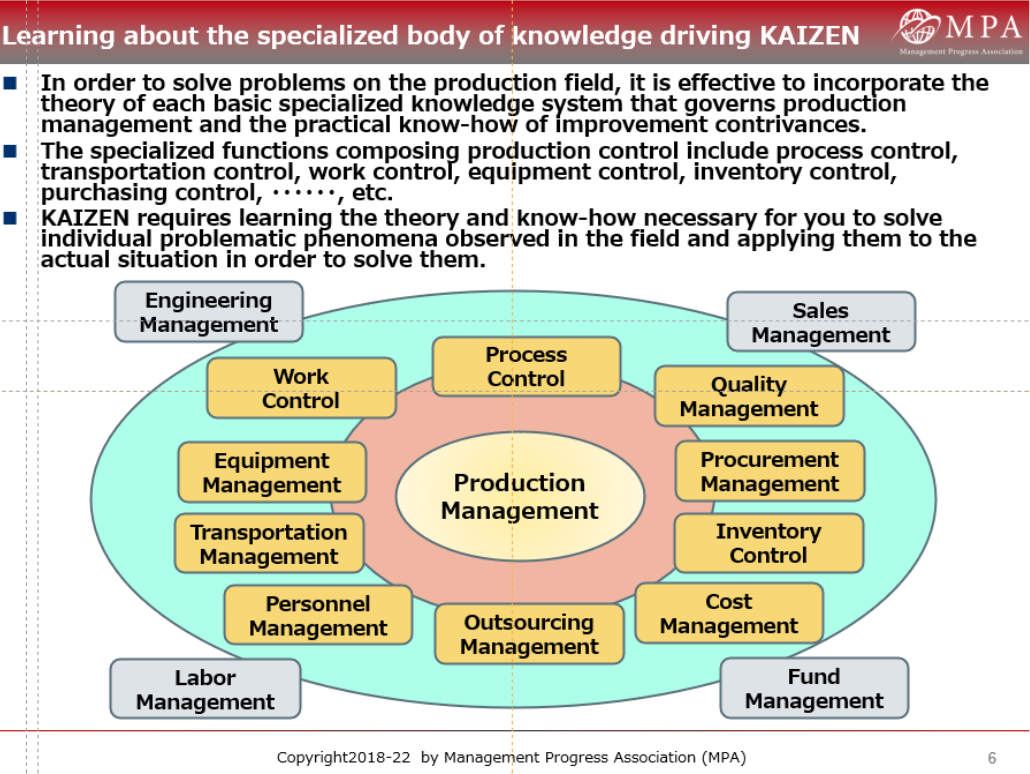

It is necessary to learn and acquire “Production Management Technique” composed of respective specified body of knowledge systems and know-hows, which enables you to control manufacturing activities in the factories.

The followings show a set of fundamental specialized elements of management and control in production.

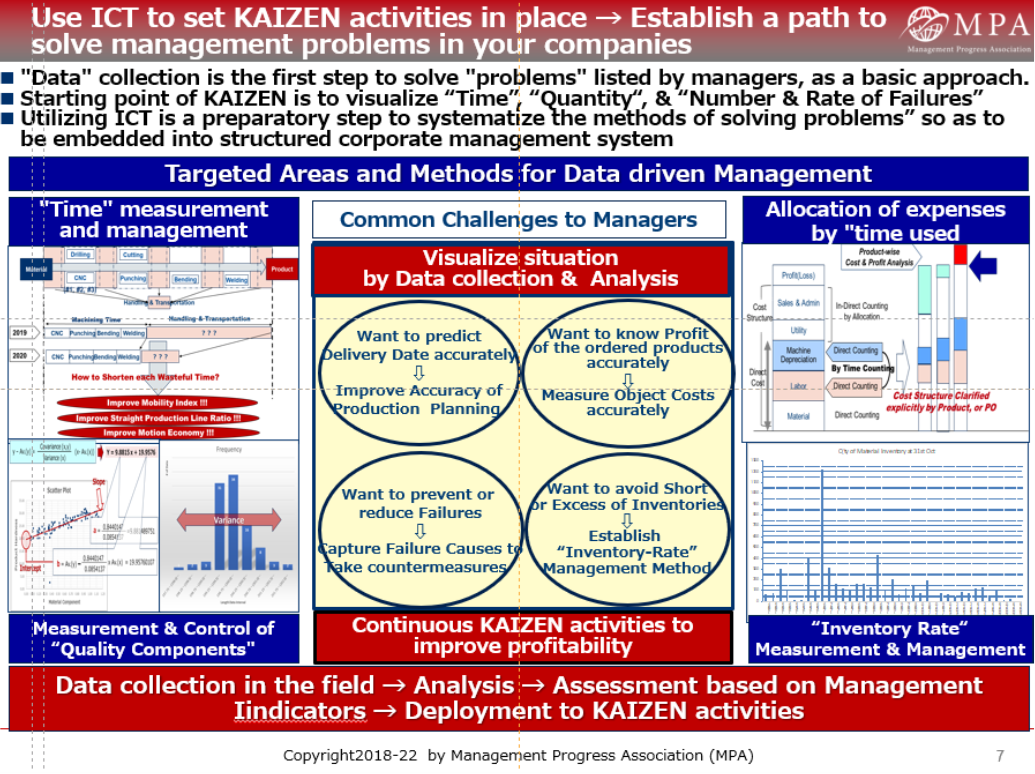

Common issues listed by lots of CEOs can be summarized into four (4) factors of “Delivery Date Designing”, “Cost or Profit Designing”, “Quality Improvement” and “Production Capacity Expansion”.

Unless introducing “Method of Data Driven Management” or “Collecting and Analyzing of Data”, you cannot solve the above problems. Then, what kind of Data do you gather up?

Key factors governing Delivery Date, Cost and Production Capacity can be grasped by starting with measuring “Time”. And obtaining key factors governing Quality is to measure actual Data resulted into “Size”, “Shape”, “Form” or “Configuration” of the produced after having been manufacture in comparison to the required specifications thereof ordered by customers

In order to analyze the collected Data, you need to apply Statistical Technique of Analysis to them. In order to achieve your goals in terms of improving efficiency such as shortening production-time, reducing failure ratio, you are going to work on turning a cycle of PDCA(Plan-Do-Check-Action) in “Problem Cause Analysis→Working out Countermeasure→Verification and Analysis of the Result” by building a Team in the fields of your manufacturing factory.

Setting the improved results by KAIZEN in place within your organization can be brought into reality only by visualizing what you have achieved by KAIZEN activities and introducing “Software System or ICT Investment” in manufacturing operation to standardize the production management processes as a routine business system.

Tsuyoshi Negishi 【5S・KAIZEN】

Career & know-how

- Design, development, production, assembly management, sales planning etc. experience in the manufacturing industry

- Many teaching experience to lecturers and companies of 5S · Kaizen

- Instruction as a management consultant (Aluminum casting factory, Saitama prefecture enterprise etc.)

- Diagnosis and guidance to SMEs as instructors at Tokyo Chamber of Commerce

- AOTS (Association for Overseas Industry Human Resources Development)

- Productivity Headquarters ((993-95 years: Russia · Moscow: spinning factory etc.)

- International Cooperation Organization JICA (1996 -: Bulgaria Quality and Productivity Center / Small and Medium Enterprise Agency, Republic of Serbia and Montenegro, Russia)

Remarks

- Graduated from Waseda University, Faculty of Engineering Science and Engineering

- Japan Productivity Center Small Business Management

- Consultant Training Course End

The mark ※ means the mandatory items

Put the necessary information in, then click “Send” button.

Write the email address in by half-width alphanumeric character, and please check up to see if any mistake is not written in.

The information you have written in will be sent to your email address you have registered.

We recognize our KAIZEN Coaching is useful and contributing to autonomous development and growth of Manufacturing and Service Industries which are requiring workers to learn and acquire the knowledge, skills and experience for enhance working quality and efficiency step by step, especially in the emerging countries.

View-points of 5S and KAIZEN are supposed to be an entry point for diagnosing the existing problems and planning how to improve the issues. In order to solve the problems fundamentally, you have to select and apply engineering technique of the particular underlying technology enabling for you to achieve improvement for the specific problems. This means you need to get cooperation from people who have respectively such variety of specialized techniques, know-how and experience as electrics, mechanics, water and energy management, civil engineering and construction and so on, depending on each different characteristic of the problems you are facing.

We have started our activities in Vietnam, such as Ho Chi Minh City, Hanoi, Hai Phong, based on the several background. We are taking time in expanding to other countries in Asia, step by step.

Now in Vietnam, VJCC (Vietnam Japan Institute of Human Resources Development), who is jointly established and operated by Japan Center of JICA (Japan International Cooperation Agency) and Foreign Trade University, has been working together with MPA to introduce MPA’s KAIZEN Coaching services to the companies whose top executives are the alumni of VJCC’s KEIEIJUKU which has been providing the 10-month training of practical knowledge and know-how of cooperate management for the participants since 2009. When MPA has been providing KAIZEN Coaching on Hands-On basis for Vietnamese companies to improve their productivity in the factories, VJCC has been assisting MPA and coordinating for those client companies. In addition, VJBEC (Vietnam Japan Business Exchange Club), which are organized by the business executives in Ho Chi Minh City area, and Vietvang, whose CEO had studied and been experienced of working in Japan. have been supporting MPA since 2018.

★If you are currently active seniors or potential seniors who are interested, please post to "Contact". The Chairman will reply.